2. Cutting Size can choice Roller shear,Plasma Cutting or saw cutting.

3. it can produce round duct with maxmum-thickness diameter 1.4mm,both of its intensity and airproofing are perfect, all kind of diameters round change rapidly with a synchronization cutting-off device.

|

Round Spiral Duct Making Machine

1.By forming the first mold design, molding to ensure standardization, easy to install. Formed to ensure efficient high-quality sealing seams and high strength. Replacement of mold and easy operation, fast.

2. Cutting Size can choice Roller shear,Plasma Cutting or saw cutting.

3. it can produce round duct with maxmum-thickness diameter 1.4mm,both of its intensity and airproofing are perfect, all kind of diameters round change rapidly with a synchronization cutting-off device.

4. Its processing speed is fast and the capacity is steady, all these are product according to Europe standard, its capacity is up to the European standard

|  |

In a given processing of the diameter of the spiral duct diameter scope, the need for pipe die, using different lengths of steel belt, through the proper installation and debugging steel band instead of pipe die. The diameter of the product determines the speed of production, the smaller the diameter, the faster the production speed, on the contrary, the larger the diameter, the slower the production speed, because of the large diameter of the spiral duct, the load on the machine is higher. The length and can be used according to demand, and high-speed synchronous automatic cutting system for cutting. Due to the aesthetic appearance of this duct, this machine has also received considerable attention and many customers have given such machines a high rating. The spiral air duct forming machine is mainly used for making round spiral air duct. The machine can automatically complete round spiral tube with different diameters and different lengths based on customers demand. Fodi company adopts the principle of using duct mold to form the spiral duct. Spiral duct machine is easy to operate and fast to form duct with accurate diameter. The spiral duct forming machine needs to be used with round elbow machine, angle steel round rolling machine and etc, to complete the other work steps needed in spiral duct processing, Fodi company produces spiral duct forming machine and round elbow machine, angle steel round rolling machine and other equipment with high quality, also ensure that the pipe size processed out of precise appearance beautiful. So it can effectively help customers greatly improve the competitiveness of their products, Spiral duct machine has always been the most important equipment for round spiral duct. In order to make our products more competitive, we have optimized the structure of the machine for many times to make our machine has been greatly improved in speed and molding effect, and it has won unanimous praise from customers all over the world.

(Model) | FODI-2-2000 | FODI-1.2-1500 | FODI-1.2-1500 |

(mm) | 200-2000 | 100-1500 | 80-1500 |

(mm)Thickness Range,Gal,Al | 1.0-2.0 | 0.5-1.2 | 0.5-1.2 |

(mm)Thickness Range(Stainless) | 0.5-0.8 | ||

(Coil Width) | 137 | 137 | 137 |

(Work Speed) | 0-40 | 0-40 | 0-40 |

(Seam Size) | Indisde or ourside | ||

(Cutting Size | (Roller shear) | ||

(Kw)Motor Power | 25 | 19 | 14.5 |

(Kg)Weight | 2500 | 2000 | 1800 |

(mm) Dimension | (Main Machine)2500mmx1900mmx1500mm | (Main Machine) 3400x1800x1800 | (Main Machine)1600x1200x1350 |

Decoiler 1500mmx1000mmx1300mm | Decoiler 1500mmx1000mmx1300mm | Decoiler 1500mmx1000mmx1300mm | |

table:2000x1200x1000mm | table:2000x1200x1000mm | table:2000x1200x1000mm |

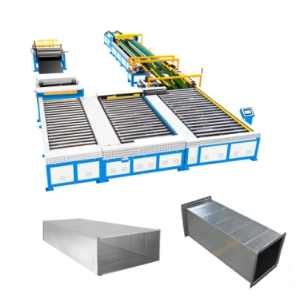

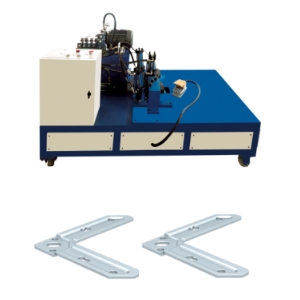

Air Duct Automatic Production Line VIII |  Air Duct Flange Corner Installation Machine | Flexible Air Duct Connector |  TDC Duct Flange forming machine |

Fodi Machinery Co.Ltd Development History

★ Profound experience in HVAC Ducting Machinery (Since 1988).

★ Profound experience in Automatic Spiral Duct Forming (Since 2004).

★ Profound experience in Automatic Duct Production Line (Since 2006).

★ Have the largest inventory for HVAC Duct Making machines in the industry.

★Got Pantened for Fire Damper Series

★ The real manufacturer with the most complete varieties of HVAC Ducting Machinery in China.

★★★Fodi company can give you both CNC duct production line machine which can manufacture air duct automatically. We will suggest a whole machines series in accordance with different customers needs★★★